redevelopment

Short response time – correct procedure – good result

Cleaning / refurbishment of electrotechnical equipment after fire damage.

If hydrogen chloride is released in gaseous form during a fire, the contamination is usually distributed throughout the entire plant.

If the chloride contamination is greater than 10 µGr./cm², then the contamination must be removed as quickly as possible, this is only possible with an aqueous cleaning process.

The goal of cleaning is the complete removal of pollutants.

Important:

Short response time – correct procedure – good result

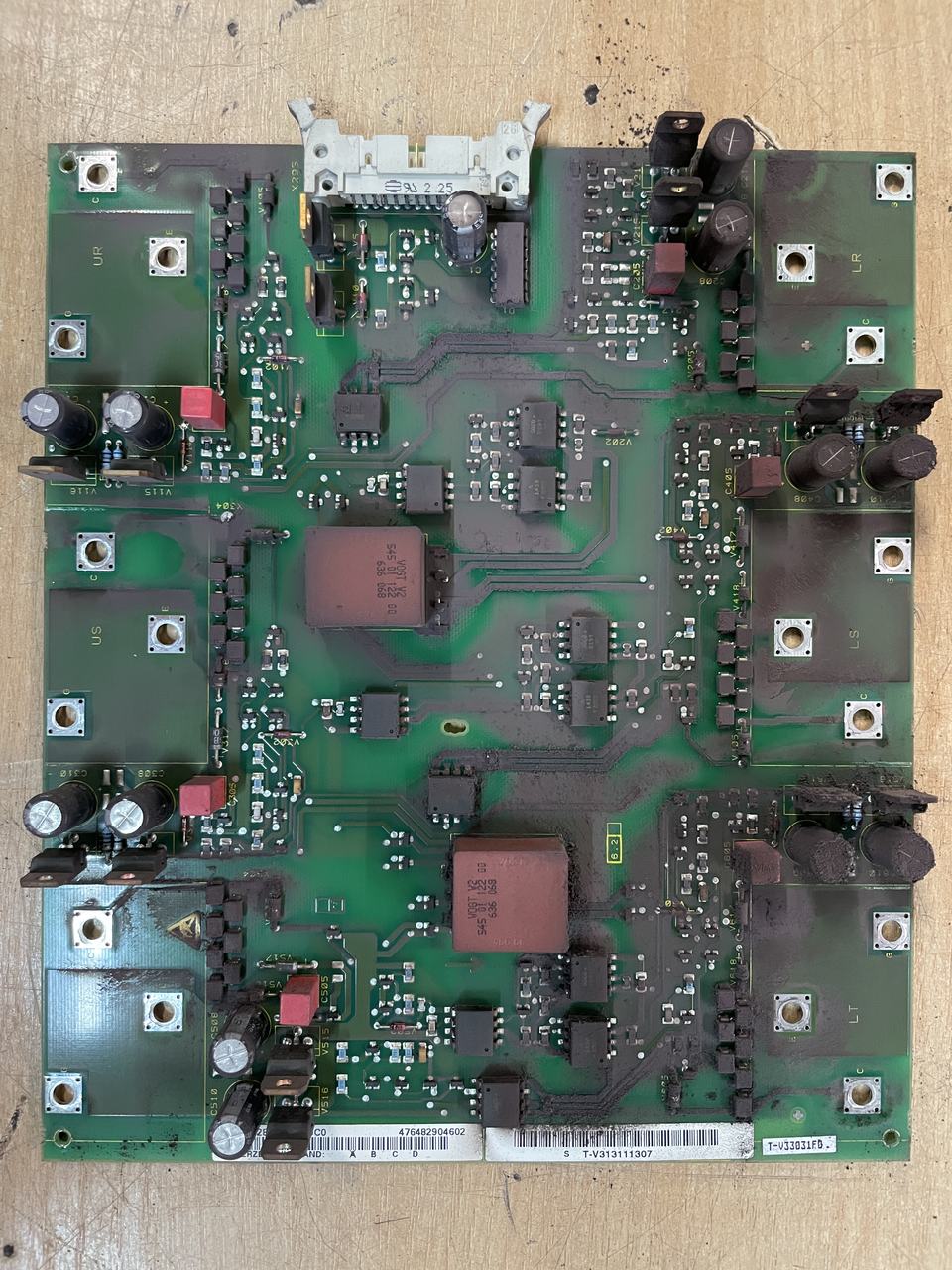

BEFORE

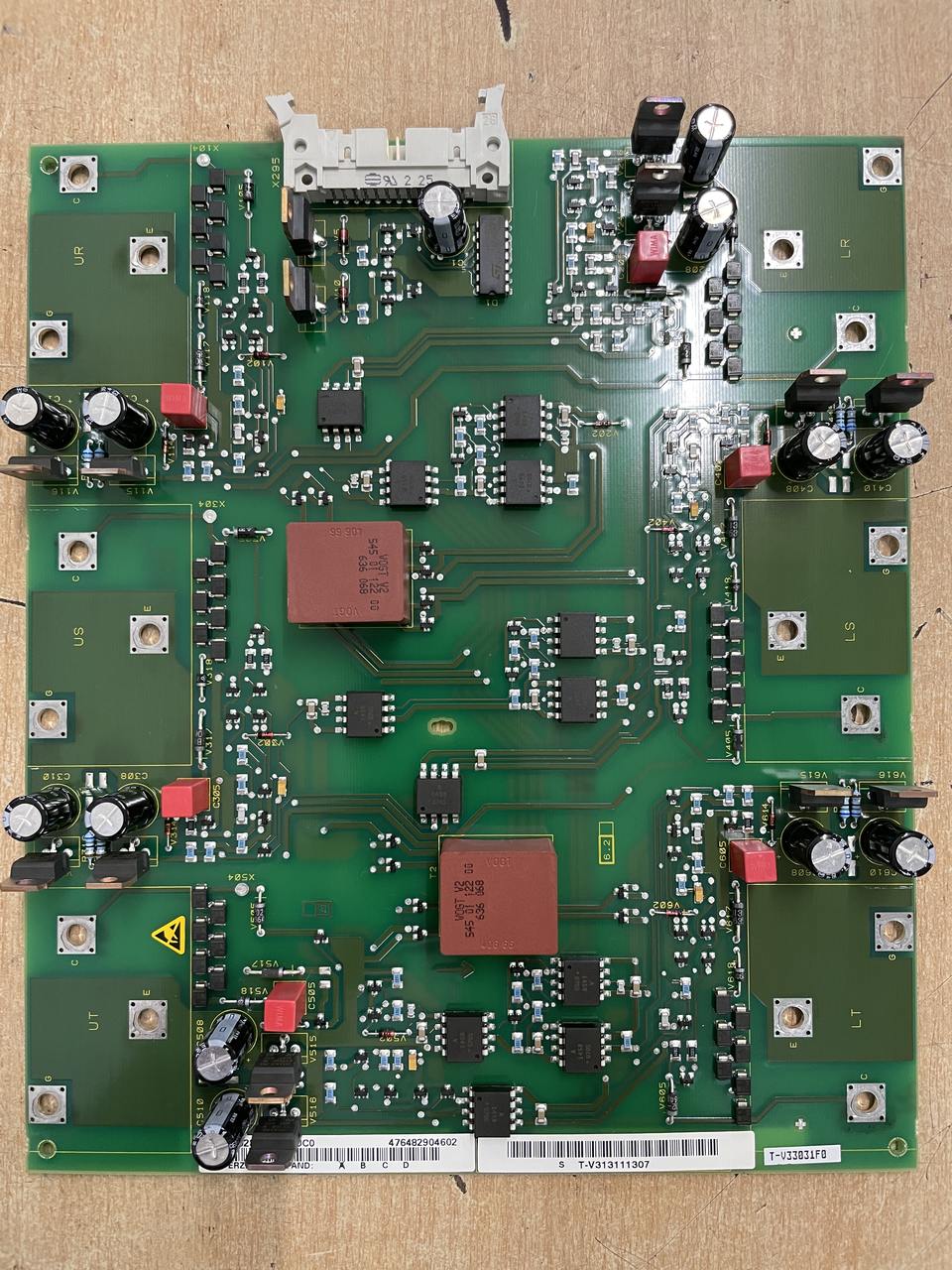

AFTER

Soot condensates are usually electrically conductive in combination with atmospheric moisture. This leads to sporadic malfunctions in electrical and especially in electronic systems. In today’s electronic assemblies with SMD technology, the insulation distances are so small that even single soot flakes can lead to failures of the assembly.

When PVC burns in a fire, hydrogen chloride is released. This can lead to significant corrosion damage.

This occurs depending on the contamination, with a time lag and is thus often neglected, the longer the remediation measures are delayed, the greater the effort and thus the cost of restoring the plant.

First steps after fire damage has occurred:

- Access control of the rooms / buildings, because possibly harmful substances were released

- Initial measures to be carried out by specialist companies only

- Keep rooms closed and lower humidity to approx. 25 – 40 % rel.F.

- Remove loose soot deposits with appropriate vacuum cleaners with filter class H

- Only after these steps, the actual refurbishment of the electrotechnical components can be started.